Two years ago I drew up a design for a sign for the MultiCam office. The project never proceeded. But last week I received a request to finally produce the sign.

The logo had changed since the first design and so when I made up the vectors for the sign I incorporated the new logo.

With the design opened in EnRoute I first separated the elements into the three layers. Each layer would be routed from 2" thick 30 lb Precision Board.

The first layer was the face of the sign with three pillow blocks for the bearings. The sign face was made into a two inch high flat relief.

The bearing blocks were then created as separate flat reliefs 1.75" tall.

The lettering and round fasteners were sunk into this relief using the subtract from relief command.

The corner allen head fasteners were sunk into the corners using the same subtract from relief tool.

The bearing shafts were created in a similar manner. I then combined the bearing blocks and sign face.This completed the first relief.

Then it was on to the second layer down. I first created the body of the sign as a 2" thick flat relief.

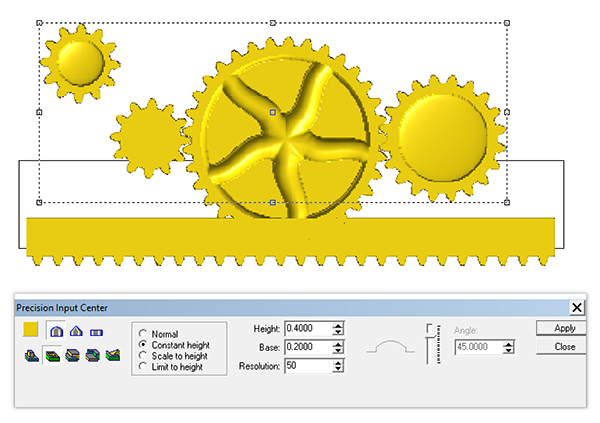

Then the gears were created as a flat relief 1.75" thick.

The centres of the gears were then dished out using the subtract from relief and the dome tool.

The gear centres were also created as reliefs 2' tall.

All of the pieces were then combined and/or merged highest to form one relief.

The back relief was a little trickier. I first used the dome tool to create a relief. I used the constant height function so I could set the height to 1.5".

I then created a zero height relief which was smaller than the outside diameter of the gear ring. This flat relief was merged highest with the spoked wheel and this procedure cropped the spoked ring.

The gear ring was then created as a flat relief 1.75" tall.

I then created a 2" flat relief. I merged (highest) everything to a zero height relief.

The three files were routed using a 1/4" ball nose bit and a high overlap.

Once routed I fit and glued up the three layers of the sign. I then hand textured the entire sign using a hand held die grinder. This will make the sign much more interesting as we paint it. The sign measures about six feet wide. Stay tuned for the painting process...