The arm relief was merged highest with the zero height relief by using the merge highest command.

I then opened the extract slice function in EnRoute. The dialogue box immediately informs me of the thickness of the piece I have created... in this case 2.39". But at this point I only wanted to slice the bottom off effectively cutting my piece off of the zero height relief.

After hitting the green check mark I immediately saw the outline of the robot arm. I could then delete the flat, zero height relief.

With the robot arm complete (for now ) it was time to urn my attention to the decorative base plate. I first used the offset drawing tool to create a border around the plaque and also Jeff's name.

The border (base relief) was built as a flat relief.

I then used the dome tool to lift the centre portion.

I used a texture batman called 'wiggly worms' to add the texture using the lettering outline as a mask so no texture went there.

I then used the lettering outline vectors to modify the base relief and raise this area above the texture.

I then used the lettering vectors and the prismatic tool to create the raised lettering. I used the constant height function to create a nicer bevel on the letters.

I then created the pedestal be for the robot arm by creating a new relief as a flat shape. In the front view we can see that is is too short. Fixing this is a simple matter of using the up arrows (in the front view) to nudge it up until I was happy.

The rivets were then built on top of this shape using the dome tool.

This pedestal relief was modified one last time by adding to the top of it to create the mounting point for the robot arm.

I then merged (highest) these two reliefs.

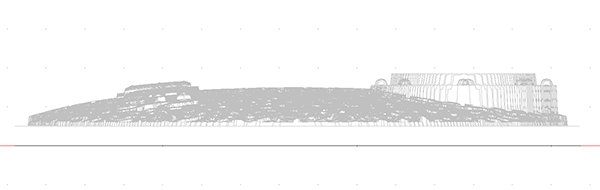

Checking in the front view I liked how everything worked.

I then selected both reliefs and brought them down to the bottom of the box. I adjusted the size of the pieces until they fit into a 2" thick plate with the exception base pedestal of the robot arm. We will next do a lice maneuver to be able to cut it out of a 2" thick piece of Precision Board. That will be saved for the next post.