As always we start with the vectors, this time done in Illustrator as I am familiar with the way the type is edited along the curve. This vector file was imputed into EnRoute and then enlarged to be the correct size.

M first step was to put an outline which we would use to create a raised border a little further along.

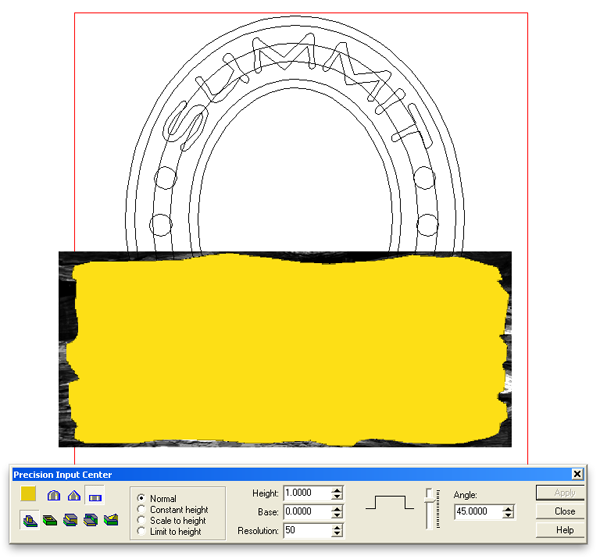

Then I imported the driftwood bitmap from the ROUTER MAGIC collection. I sized the bitmap, centered it and then traced a vector outline.

Then I created a flat relief using this vector.

Next I applied the bitmap to the relief using a value of 0.3" This means the blacks do nothing, the white raises by 0.3" and the grays do something in-between.

I then used the relief modeling tools to carve in some extra depth into the woodgrain. It took only a few seconds to get the effect I was after.

The oval was the next relief to be created. It was done as a flat relief.

The flat oval border relief was then modified by doming up the center with a raised base to give it a bit of an edge.

The bottom lettering border was then created as a separate flat relief. (in both copies of the sign. ) I then selected the oval and driftwood reliefs and combined them to form one relief.

I then positioned these new lettering border reliefs and merged them highest with the base reliefs.

Lastly I used the dome tool to modify the base relief using the SUMMIT letter and circle vectors.

As easy as that we had a routing file ready to tool path and send to the MultiCam.

My big compressor packed it in yesterday. It had been acting weird of late and I decided I would get a new one and then rebuild the old as a standby. Luckily I had already placed an order for a new one last week. It will be a while before the new one arrives so I will have to wait to route these pieces. In the mean time I have plenty of other things to do Stay tuned...