There is a large white metal door behind the Fox & Hounds Pub bar that looks sorely out of place. The door leads to the large cooler that holds all the beer. Our task is to make it fit into the rest of the decor. The solution was to route a door skin from 40 lb Precision Board which we'll fasten to the door.

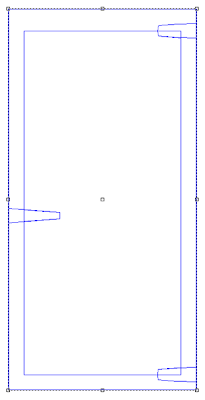

The hardware (hinges and closures) was not movable. We had to work around them. Because the door is high traffic we decided to stay away from the edges 3". This will minimize the chances of damage down the road. I drew up a template in EnRoute from careful measurements taken on site.

The next step was to create the individual planks for the wood grained door. I first drew the gaps between the planks, then used the jigsaw tool to create the individual planks. This was the fastest way to get everything to line up as it should.

Square rivet heads (with rounded corners) were next to be added.

I used the horizontal and vertical woodgrain bitmaps from my TEXTURE MAGIC collection to create the woodgrains. The bitmaps were enlarged enough to fit across each plank and then applied with a value of 0.15" for the depth.

The result was some pleasing woodgrain that looked cool already.

The next step was to create the rivets. These were created as separate reliefs using the bevel tool. Once I had floated them into position I merged highest to make them part of the door panel.

The name plate was the next order of business. It was a simple oval shape. with some round rivets.

I used another bitmap from the TEXTURE MAGIC collection called splotches 1 to create a beaten copper look for the name plate.

Then I added a low lettering border and the beveled lettering as a last step.

As quick as that the door skin was ready for tool pathing. I did a rough pass with a 3/8" ball nose bit at 50% and then a final pass with a 1/8" with a 75% overlap. Then I sent it to the MultiCam.

Next up is the finishing. While it routes I'll be working on one more very cool sign for the pub. Stay tuned...

-dan